- viscosity

- modulus of elasticity

- relaxation modulus

- creep parameters

- viscoelastic parameters

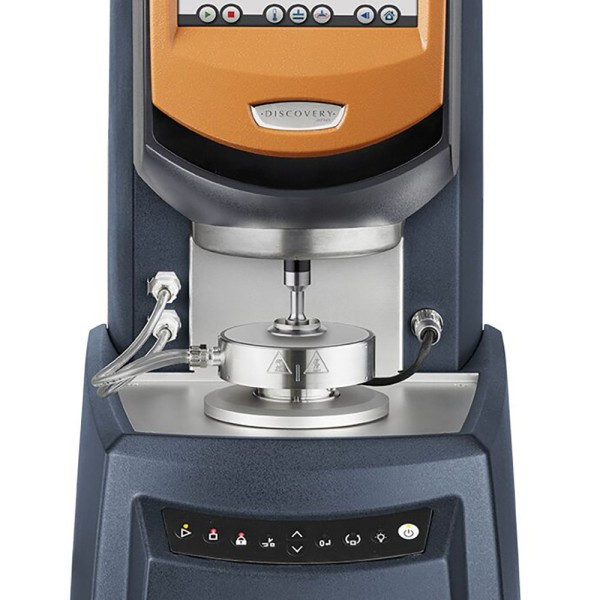

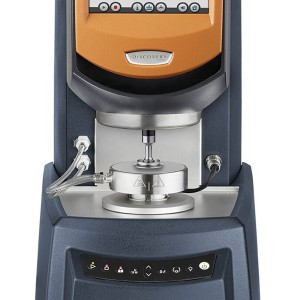

Discovery HR x0

Hybrid Rheometers Series

| Manufacturer

TA Instruments |

|

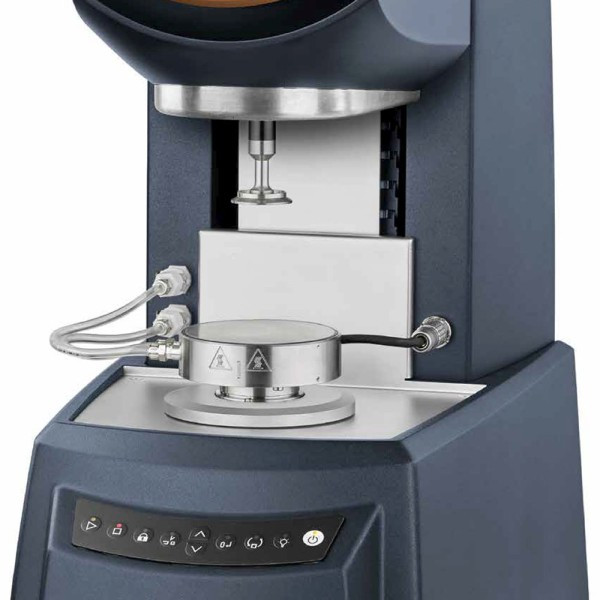

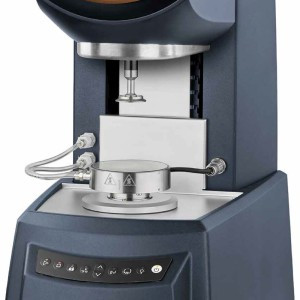

Discovery HR x0 is a series of new-generation hybrid rheometers that deliver precise rheological measurements for a wide set of modes: controlled stress, strain or rate; steady shear or oscillation; rotational, tensile, compressive or extensional deformation.

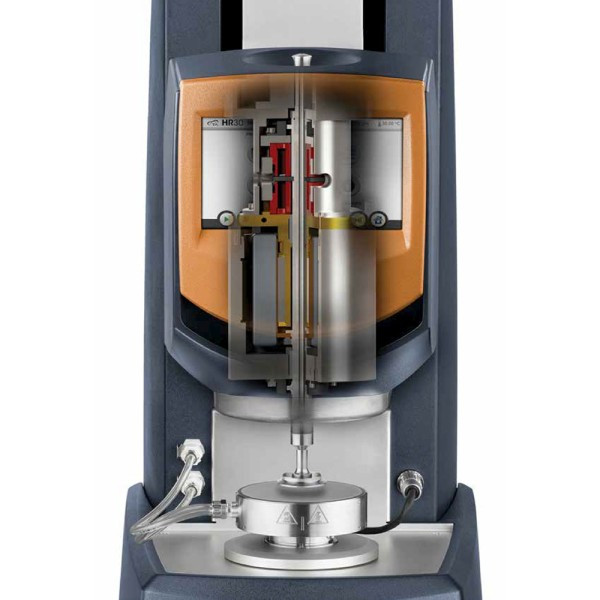

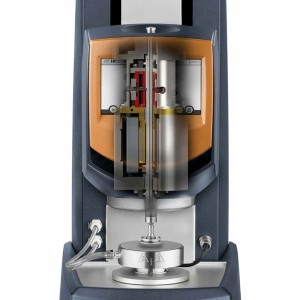

Superior performance. A rheology data accuracy, first of all, depends on the fundamental measurements of Torque (stress) and Displacement (strain). Compared to existent analogues, Discovery HR x0 has the advantages:

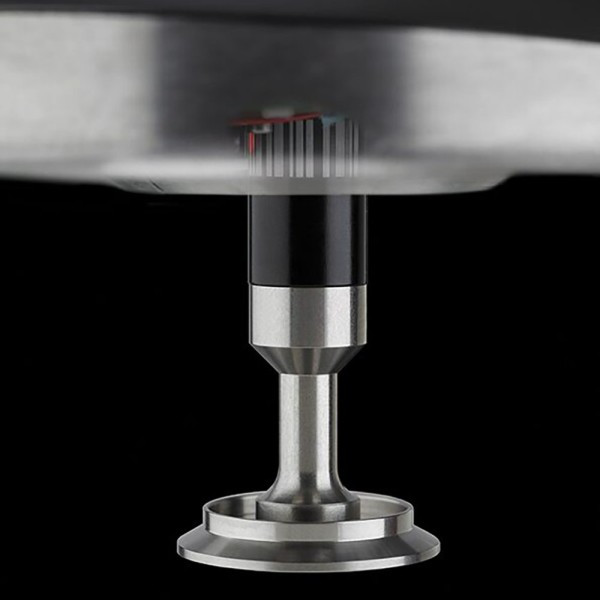

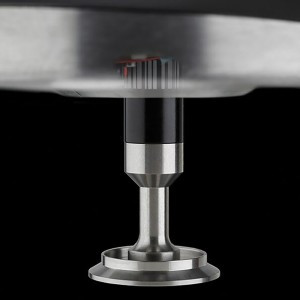

- the highest torque sensitivity – due to the patented Magnetic Bearing, decreasing friction by >70% (vs. air bearings), enabling accurate low-stress measurements such as yield stress and zero-shear viscosity;

- the best displacement resolution – due to the patented Optical Encoder Dual Reader, enabling the most precise measurements of shear rate and small amplitude oscillatory strain.

Ease of Use. Discovery HR x0 is designed to enable every operator to get the most accurate rheology data. Convenient features such as integrated sample lighting and an intuitive touchscreen make sample loading easy and repeatable. TRIOS Express software has test methods are streamlined in for routine testing, while TRIOS Unlimited allows complete customization for advanced characterization.

Versatility. A wide range of accessories is available for Discovery HR x0 allowing the rheometers to be configured for various experimental needs. SmartSwap geometries and accessories are quickly installed and automatically identified, that is actual for labs supporting a growing range of materials and testing requirements. A possibility to operate in a glovebox provides reliable rheological data of atmosphere sensitive samples.

- Support all widespread types of measurement geometries: plate/plate, cone/plate, concentric cylinders

- Wide ranges of a mechanical stress and a deformation rate

- Rheological measurements with the Fourier transform

- Tests of materials with various chemical and physical properties with an aggregate state from liquid to solid one

- Dynamic Mechanical Analysis (tension, compression, torsion, bending of a bar with free and fixed end points)

- Tribology analysis

- Dielectric analysis

- Measurement under action on a sample of different controlled conditions: temperature, pressure, electrical current, magnetic field, humidity, UV radiation

- Possibility of joint operation with the Raman spectrometer, microscope, Small Angle Light Scattering system

|

Specifications

|

HR 10

|

HR 20

|

HR 30

|

|---|---|---|---|

|

Bearing Type, Thrust

|

Magnetic

|

||

|

Bearing Type, Radial

|

Porous Carbon | ||

|

Motor Design

|

Drag Cup | ||

|

Minimum Torque, Oscillation [nN∙m]

|

5

|

1

|

0.3

|

|

Minimum Torque, Steady Shear [nN∙m]

|

5

|

3

|

1

|

|

Maximum Torque [mN∙m]

|

200 | ||

|

Torque Resolution [nN∙m]

|

0.1 | 0.05 | |

|

Minimum Frequency [Hz]

|

10-7 | ||

|

Maximum Frequency [Hz]

|

100 | ||

|

Minimum Angular Velocity (1) [rad/s]

|

0 | ||

|

Maximum Angular Velocity [rad/s]

|

300 | ||

|

Displacement Transducer

|

Optical Encoder | ||

|

Optical Encoder Dual Reader

|

N/A

|

Standard

|

|

|

Displacement Resolution [nrad]

|

10 | 2 | |

|

Step Time, Strain (2) [ms]

|

15 | ||

|

Step Time, Rate (2) [ms]

|

5 | ||

|

Normal/Axial Force Transducer

|

Force Rebalance Transducer (FRT) | ||

|

Maximum Normal Force [N]

|

50 | ||

|

Normal Force Sensitivity [N]

|

0.01 | 0.005 | |

|

Normal Force Resolution [mN]

|

1 | 0.5 | |

(1) Zero in controlled stress mode. Controlled rate mode depends on duration of point being measured and sampling time

(2) Results at 99% of commanded value

| Features (3) | HR 10 | HR 20 | HR 30 |

|---|---|---|---|

| Optical Encoder Dual Reader | – | ● | ● |

| Dynamic Mechanical Analysis (DMA) | – | ○ | ● |

| True Position Sensor (TPS) | ● | ● | ● |

| Controlled stress (steady, transient, oscillation) | ● | ● | ● |

| Controlled strain (steady, transient, iterative oscillation) | ● | ● | ● |

| Direct Strain (oscillation) | ○ | ● | ● |

| Fast data collection

|

– | ● | ● |

| Normal Force measurements with FRT | ● | ● | ● |

| Axial and tack testing | ○ | ● | ● |

| One-Touch-AwayTM Display | ● | ● | ● |

| Integrated Sample Lighting | ● | ● | ● |

| FastTrack | ● | ● | ● |

| AutoPilot | ○ | ○ | ○ |

(3) Keys: ● Included; ○ Optional; – Not Available

| DMA Mode Specifications | |

|---|---|

| Motor Control | Force Rebalance Transducer (FRT)

|

| Minimum Force in Oscillation [mN]

|

3

|

| Maximum Axial Force [N]

|

50

|

| Minimum Displacement in Oscillation [μm]

|

0.01

|

| Maximum Displacement in Oscillation [μm] | 100 |

| Axial Frequency Range [rad/s]

|

6×10-5 … 100

|

| Axial Frequency Range [Hz]

|

10-5 … 16

|

- Peltier Plates

- Advanced Peltier Plate

- Upper Peltier Plate

- Dual Stage Peltier Plate

- Electrically Heated Plates

- Upper Heated Plate

- Peltier Concentric Cylinder

- Electrically Heated Cylinder

- ASTM D4092 – Standard Terminology for Plastics: Dynamic Mechanical Properties

- ASTM D4440 – Standard Test Method for Plastics: Dynamic Mechanical Properties Melt Rheology

- ASTM D4473 – Standard Test Method for Plastics: Dynamic Mechanical Properties: Cure Behavior

- ASTM D5279 – Standard Test Method for Plastics: Dynamic Mechanical Properties: In Torsion

Brochures

- HR 30/20/10 Discovery Hybrid Rheometer. – TA Instruments, 2021.

- Discovery Hybrid Rheometers Temperature Systems and Accessories. – TA Instruments, 2022.

Application Notes

- Rheological evaluation of battery slurries with different graphite particle size and shape : RH119. – TA Instruments.

- Powder rheology of graphite: Characterization of natural and synthetic graphite for battery anode slurries : RH125. – TA Instruments.

- Shear and flow properties of an NMC based dry cathode powder : RH136. – TA Instruments.

- Characterization of LIB cathode slurries using simultaneous measurements of rheology and impedance spectroscopy : RH137. – TA Instruments.

- Characterization of UV curing resins for photo-curing 3D : RH118. – TA Instruments.

- Understanding of rheology of polymers : AAN013. – TA Instruments.

- Understanding rheology of structured fluids : AAN016. – TA Instruments.

- Powder rheology of lactose: Impacts of powder morphology on performance of pharmaceutical excipients : RH123. – TA Instruments.